Benchmarking: Bond/Barratt - Selbaie

Contents

Benchmarking: Bond/Barratt Specific Energy Consumption - Selbaie

Duval, L. and Wood, K., Testing, Design and Operation of SAG Circuit at Les Mines Selbaie, Proceedings of the SAG 1989 Conference, Vancouver, Canada, September 1989.

Wood, K. and Duval, L., Mill Expansion at Les Mines Selbaie, Proceedings of the 25th Anniversary Issue of the Canadian Mineral Processors, Ottawa, Canada (Paper № 8), January 1987.

Design Criteria

Two surveys was conducted in Nov 1988 and Dec 1988 and reported the following:

- Ore laboratory Bond rod mill work index: 16.5 metric

- Ore laboratory Bond ball mill work index, 104 µm closing mesh: 12.2 metric

- Ore laboratory Bond ball mill work index, 37 µm closing mesh: 13.2 metric

- MacPherson Autogenous work index (gross) of 20.1 metric (to 332 µm)

- MacPherson Autogenous work index (corrected) of 15.8 metric (to 332 µm)

- MacPherson ball mill operating work index of 13.8 metric (to 48 µm)

- MacPherson AB circuit operating work index of 16.1 metric (to 48 µm)

- Circuit FAG mill feed F80 117 mm

- Circuit transfer size T80</sub) 325 µm

- Circuit cyclone overflow P80 44 µm

- Circuit SAG operating work index of 20.0 metric (to 325 µm)

- Circuit ball mill operating work index of 13.8 metric (to 45 µm)

- Circuit total operating work index of 16.0 metric (117 mm to 45 µm)

- Target throughput: 5000 t/d at 90% availability

- Actual throughput:

The motors are described as:

- SAG mill is gear-driven with a DC variable speed motor having electrical efficiency of 0.925.

- SAG mill maximum speed (for "design" ore hardness) is 74% of critical speed.

- Ball mill is gear-driven with a fixed-speed synchronous motor (assume 0.96 electrical efficiency)

Additional data:

- SAG mill dimensions are given as 27 ft diameter by 11 ft long (not clear if this length is f/f or EGL)

- Checking the Metso installation list, a 27 ft by 12 ft f/f long SAG mill was delivered to Quebec in 1985.

- Duval & Wood (1989) say the discharge chamber is smaller than normal, so model a 10.5 ft EGL mill.

- Liner drawings show SAG mill hi/lo pattern with roughly 6 inch effective thickness.

- Ball mill dimensions are given in Wood & Duval (1987) as 16.5 ft diameter by 25.5 ft (?? f/f or EGL ??)

- Checking the Metso installation list, a 16.5 ft by 25.5 ft f/f long ball mill was delivered to Quebec in 1985.

Model parameter fitting

No crushing work index is provided, but we can make an assumption it is similar to the MacPherson Autogenous Work Index measured at Hazen.

No power draw numbers or mill filling values are given for the SAG or ball mill; only specific energy and work index values are provided. Assume for modelling:

- SAG mill filling is 25% v/v (gives about 85% of total power draw, sounds reasonable)

- ball mill filling is 32% v/v (gives about 95% of total power draw, sounds reasonable)

| FAG | BM | Peb Crusher | Etotal | |

|---|---|---|---|---|

| DCS kW | 6,667 | 5,082 | ||

| Shell kW | 6,208 | 4,732 | 224 | |

| Throughput, t/h | 650 | 650 | 650 | |

| Specific Energy, kWh/t | 9.55 | 7.28 | 0.34 | 17.18 |

| Essbm | 16.82 | |||

| contingency | 2.1% |

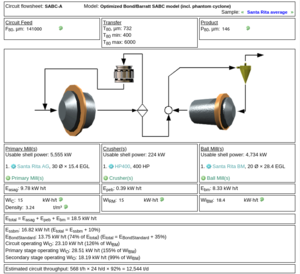

Circuit Simulation

Combining the Bond/Barratt specific energy model, the Austin FAG model described in the bibliography and the Nordberg wet overflow ball mill model described in the bibliography results in the following throughput predictions using the work index values above:

- Actual FAG/ball motor powers (at shell): 6,208 kW / 4,732 kW

- Actual daily average throughput: 650 tonnes/hour

- Predicted FAG/ball motor powers (at shell): 5,555 kW / 4,734 kW

- Predicted nominal throughput: 568 tonnes/hour (14.4% difference)

Additional criteria for modelling:

- SAG mill loading 33.18% v/v (autogenous, no balls)

- ball mill loading 27.5% v/v

- DCS to shell conversion 0.97 × 0.96 = 0.9312

- SAG liner thickness not given, assume 4.5 inches

- circuit F80 141 mm; P80 146 µm

| FAG | BM | Pebble Crusher |

total | |

|---|---|---|---|---|

| Measured specific energy consumption, kWh/t | 9.55 | 7.28 | 0.34 | 17.18 |

| Predicted specific energy consumption, kWh/t | 9.78 | 8.33 | 0.39 | 18.50 |

| Difference, kWh/t | 0.23 | 1.05 | 0.05 | 1.32 |

| Difference, % | 2.4% | 14.4% | 14.7% | 7.7% |