Difference between revisions of "Model:Bond RMBM Model"

| Line 15: | Line 15: | ||

=== Formulae === |

=== Formulae === |

||

<math> |

<math> |

||

| − | E_{RM} = Wi_{RM} \times \left ( \tfrac {10}{\sqrt{ T_{80} }} - \tfrac {10}{\sqrt{ F_{80} }} \right )\times EF_4^{RM} </math> |

+ | E_{RM} = Wi_{RM} \times \left ( \tfrac {10}{\sqrt{ T_{80} }} - \tfrac {10}{\sqrt{ F_{80} }} \right )\times EF_4^{RM} \times EF_6 \times EF_8 </math> |

| + | |||

<math> |

<math> |

||

E_{BM} = Wi_{BM} \times \left ( \tfrac {10}{\sqrt{ P_{80} }} - \tfrac {10}{\sqrt{ F_{80} }} \right ) \times EF_4^{BM} \times EF_5</math> |

E_{BM} = Wi_{BM} \times \left ( \tfrac {10}{\sqrt{ P_{80} }} - \tfrac {10}{\sqrt{ F_{80} }} \right ) \times EF_4^{BM} \times EF_5</math> |

||

| Line 27: | Line 28: | ||

EF_4^{RM} =\left [ 1 + \left( \frac{ (0.907 \times Wi_{RM} - 7) }{ \left (\frac{F_{80} }{ T_{80}} \right )} \right) \left ( {\frac{F_{80} }{ { 16 000 \left(\frac{14.33}{Wi_{RM} } \right )^{0.5}}} }-1 \right ) \right ] |

EF_4^{RM} =\left [ 1 + \left( \frac{ (0.907 \times Wi_{RM} - 7) }{ \left (\frac{F_{80} }{ T_{80}} \right )} \right) \left ( {\frac{F_{80} }{ { 16 000 \left(\frac{14.33}{Wi_{RM} } \right )^{0.5}}} }-1 \right ) \right ] |

||

</math> |

</math> |

||

| + | |||

| + | <math> |

||

| + | EF_6 = 1 + \frac{ \left( \frac{F_{80}}{T_{80}} - R_{ro} \right)^2 }{150} |

||

| + | </math> |

||

| + | |||

| + | where, |

||

| + | |||

| + | ''R<sub>ro</sub> = 8 + 5 × (rod length) / (mill diam)'' |

||

| + | |||

| + | units aren't important as long as the mill diameter and rod length are expressed in the same units. |

||

| + | |||

| + | |||

| + | ''EF<sub>8</sub> = 1.0'' for rod mills fed by closed circuit crushing plants. |

||

| + | |||

| + | ''EF<sub>8</sub> = 1.2'' for rod mills fed by open circuit crushing plants. |

||

| + | |||

| + | |||

The ball mill oversize feed factor (EF<sub>4</sub><sup>BM</sup>) is always calculated with the ball mill work index. The optimal feed size for the EF<sub>4</sub><sup>BM</sup> is always calculated using the rod mill work index. |

The ball mill oversize feed factor (EF<sub>4</sub><sup>BM</sup>) is always calculated with the ball mill work index. The optimal feed size for the EF<sub>4</sub><sup>BM</sup> is always calculated using the rod mill work index. |

||

| Line 39: | Line 57: | ||

* P<sub>80</sub>, µm is the specified product size (hydrocyclone overflow) |

* P<sub>80</sub>, µm is the specified product size (hydrocyclone overflow) |

||

| + | Note that the EF3 factor is not used in these equations. Rowland describes omitting EF3 as a conservative design, adding a 'safety factor' to larger diameter mills. |

||

===Required parameters=== |

===Required parameters=== |

||

Revision as of 18:35, 22 June 2016

Bond/Rowland rod mill ball mill model

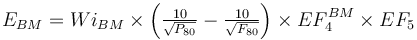

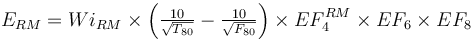

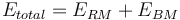

This is a rod mill feeding a ball mill model that estimates the specific energy consumption (ERM and EBM) using the Rowland interpretation of the classical Bond work index equation including Rowland efficiency factors.

There are two varieties of this model, one based on feed generated by closed-circuit crushing and other based on feed generated by open-circuit crushing.

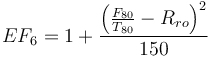

Warning: do not mix sizes of rod mills, only have a single size of rod mill in the primary section. The estimation of Rowland EF6 factors requires rod mill dimensions, and only the first rod mill in the circuit is queried to calculate the EF6.

Testwork Required

Formulae

The rod mill oversize feed factor (EF4RM) is calculated using the greater of the sample's rod mill or crushing work index (which is usually the WiRM). The optimal feed size and EF4 are both calculated using whichever is greater.

![EF_4^{RM} =\left [ 1 + \left( \frac{ (0.907 \times Wi_{RM} - 7) }{ \left (\frac{F_{80} }{ T_{80}} \right )} \right) \left ( {\frac{F_{80} }{ { 16 000 \left(\frac{14.33}{Wi_{RM} } \right )^{0.5}}} }-1 \right ) \right ]](/images/math/2/7/c/27cb6782d414da805410db603189ef54.png)

where,

Rro = 8 + 5 × (rod length) / (mill diam)

units aren't important as long as the mill diameter and rod length are expressed in the same units.

EF8 = 1.0 for rod mills fed by closed circuit crushing plants.

EF8 = 1.2 for rod mills fed by open circuit crushing plants.

The ball mill oversize feed factor (EF4BM) is always calculated with the ball mill work index. The optimal feed size for the EF4BM is always calculated using the rod mill work index.

![EF_4^{BM} =\left [ 1 + \left( \frac{(0.907 \times Wi_{BM} - 7) }{ \left (\frac{T_{80} }{ P_{80}} \right )} \right) \left ( {\frac{T_{80} }{ { 4000 \left(\frac{14.33}{Wi_{RM} } \right )^{0.5}}} }-1 \right ) \right ]](/images/math/3/4/e/34ec5343663db3e292e9c0623a6b2f89.png)

where:

- F80, µm is the specified circuit feed size (crushing plant product)

- T80, µm is the transfer size that balances the power draw in rod & ball mill stages.

- P80, µm is the specified product size (hydrocyclone overflow)

Note that the EF3 factor is not used in these equations. Rowland describes omitting EF3 as a conservative design, adding a 'safety factor' to larger diameter mills.

Required parameters

- F80, µm is the 80% passing size of the fresh feed to the circuit (expected to be a Bond-compatible size distribution).

- P80, µm is the 80% passing size of the circuit product (expected to be a Bond-compatible size distribution).

- Availability, expressed as a decimal (0.90 = 90% availability) is used to convert t/h to t/d.

Optional parameters

- Description and Comment are optional text fields

- Maximum t/h limit is a t/h throughput above which a warning message is displayed (but does not actually limit the throughput).

- T80 min and T80 min override the transfer size restrictions built into the model

- Ball mill work index adjustment used to adjust WiBM for different P80 sizes.

- coefficient (a), the fitted coefficient to the adjustment equation

- exponent (b), the fitted exponent to the adjustment equation

Secondary and tertiary crushers

The model assumes any secondary and/or tertiary crushing happens upstream of the rod mill. Crusher specific energy is not included in this model.

The choice of crushers and arrangement is normally based on volumetric flow and not on power draw. Use a crusher catalogue or another tool, like Metso's Bruno software, to determine the size and arrangement of the crushers ahead of the ball mill(s).