Model:Bond RMBM Model

Contents

Bond/Rowland rod mill ball mill model

This is a rod mill feeding a ball mill model that estimates the specific energy consumption (ERM and EBM) using the Rowland interpretation of the classical Bond work index equation including Rowland efficiency factors.

Testwork Required

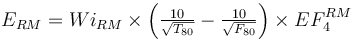

Formulae

The rod mill oversize feed factor (EF4RM) is calculated using the greater of the sample's rod mill or crushing work index (which is usually the WiRM). The optimal feed size and EF4 are both calculated using whichever is greater.

![EF_4^{RM} =\left [ 1 + \left( \frac{ (0.907 \times Wi_{RM} - 7) }{ \left (\frac{F_{80} }{ T_{80}} \right )} \right) \left ( {\frac{F_{80} }{ { 16 000 \left(\frac{14.33}{Wi_{RM} } \right )^{0.5}}} }-1 \right ) \right ]](/images/math/2/7/c/27cb6782d414da805410db603189ef54.png)

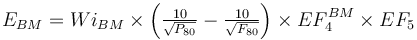

The ball mill oversize feed factor (EF4BM) is always calculated with the ball mill work index. The optimal feed size for the EF4BM is always calculated using the rod mill work index.

![EF_4^{BM} =\left [ 1 + \left( \frac{(0.907 \times Wi_{BM} - 7) }{ \left (\frac{T_{80} }{ P_{80}} \right )} \right) \left ( {\frac{T_{80} }{ { 4000 \left(\frac{14.33}{Wi_{RM} } \right )^{0.5}}} }-1 \right ) \right ]](/images/math/3/4/e/34ec5343663db3e292e9c0623a6b2f89.png)

where:

- F80, µm is the specified circuit feed size (crushing plant product)

- T80, µm is the transfer size that balances the power draw in rod & ball mill stages.

- P80, µm is the specified product size (hydrocyclone overflow)

Secondary and tertiary crushers

The model assumes any secondary and/or tertiary crushing happens upstream of the rod mill. Crusher specific energy is not included in this model.

The choice of crushers and arrangement is normally based on volumetric flow and not on power draw. Use a crusher catalogue or another tool, like Metso's Bruno software, to determine the size and arrangement of the crushers ahead of the ball mill(s).