Model:El Soldado SS SAG

Contents

El Soldado SGI Single-Stage SAG Model

Use with extreme caution, see discussion at the bottom of the page.

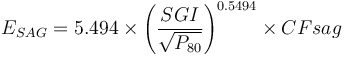

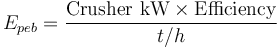

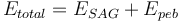

This is a model that estimates the specific energy consumption of the single-stage SAG mill at El Soldado in Chile. The circuit operates in open circuit where pebbles are rejected to a different circuit. The model is based on the equation by Amelunxen (2014) for ESAG. This single-stage SAG mill uses SGI to predict grinding down to about 200 µm with no need for a ball mill work index.

Testwork Required

Required parameters

- F80, µm is the 80% passing size of the fresh feed to the circuit (expected to be a Bond-compatible size distribution).

- P80, µm is the 80% passing size of the circuit product (expected to be a Bond-compatible size distribution).

- Availability, expressed as a decimal (0.90 = 90% availability) is used to convert t/h to t/d.

Optional parameters

- Description and Comment are optional text fields

- Maximum t/h limit is a t/h throughput above which a warning message is displayed (but does not actually limit the throughput).

- CFsag calibration factor, model tuning factor for EASAG

Formulae

This model, published by F. Jorquera & M. Becerra (Procemin 2016), is specifically calibrated to the El Soldado single-stage SAG mill (SS-SAG). The El Soldado SAG mill operates in open circuit where pebbles are rejected to a different grinding line (of crushers with single-stage ball milling). The calibration parameters are different than Amelunxen, 2014: a 7% lower value for the coefficient (5.494 versus 5.9 in Amelunxen), and a slightly different exponent (0.563 versus 0.55 in Amelunxen). The exponent is within 2% of Amelunxen's value, and the model does not account for the way El Soldado rejects uncrushed pebbles from the SAG circuit, so the SGI of the feed is slightly harder than the actual work the mill is doing.

CFsag calibration factor

The CFsag factor is used to reflect the effect of pebble crushing and pre-crushing on the overall circuit performance.

- Base value, SAB circuit (no pebble crushing, ~6 inch SAG feed), CFsag = 1.00

- Pebble crushing, SABC circuit, CFsag = 0.85

- Pre-crushing, (fine SAG feed, -120 mm SAG feedCuster et al, CMP 2001), CFsag = 0.90

- Pre-crushing and pebble crushing, CFsag = 0.85 × 0.90 = 0.77

Discussion - Use extreme caution!

The technical paper by Doll & Becerra (Procemin, 2017) compared the predictions of several single-stage SAG mill models, including the El Soldado model, to published information from five mines. The El Soldado model generally worked well at El Soldado, but gave poor predictions for nearly all the other mines in the paper. Use this model with extreme caution; the Bond/Barratt and Morrell models are much better at making predictions on a variety of ores.