Benchmarking: Bond - Esperanza

Contents

Benchmarking: Bond/Barratt SAG Mill Specific Energy Consumption - Esperanza

- Villanueva, F. and Soto, L., SEC and the impact on a mills selection for DMC project. Proceedings of the XXVII International Mineral Processing Congress, October 2014, Santiago, Chile. C14-23.

Paper describes modelling of two expansion cases (Esperanza Sur and Encuentro). Some operating data for the current Esperanza pit & plant are provided as they were used to tune the comminution models used for the expansion cases.

Design Criteria

Actual operating data from Esperanza

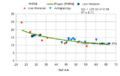

- A×b of Esperanza ore (Aug-Dec 2012); avg= 39; range is 30.7 to 45.5.

- WiBM average is 16.0 kWh/st, = 17.6 kWh/tonne.

- ESAG for "normal" blasting, average = 5.2 kWh/tonne; range is 3.9 to 7.2 kWh/tonne.

- ESAG for "high intensity" blasting typically 10% lower ESAG.

- SAG feed size range 33.6% to 49.0 percent passing 1¼ inch (32 mm).

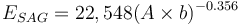

A relationship for ESAG (as kWh/tonne) to A×b is given for Esperanza operating data:

No EBM or Etotal data is provided in the paper.

Design criteria for expansion cases (which may reflect Esperanza operating conditions)

- SAG circuit F80 = 132 mm

- transfer T80 = 3500 µm (text erroneously says "3500 mm")

- BM circuit P80 = 180 µm

- SAG mill power utilization = 92.3%

- Ball mill power utilization = 95%

- Plant availability = 93%

Mill criteria

- SAG mill: 40 foot nom dia by 26 foot flange-to-flange cylinder length

- ball mill: 27 foot nom dia by 45 foot flange-to-flange cylinder length (2 units)

- SAG mill gearless motor 31,500 HP (given in Thiele & Parraguez, Relpas 2011 conference)

- Ball mill gearless motors 25,000 HP

(some references give 30,000 HP for SAG motor; this is thought to be the value excluding a 5% design margin)

Modelling

The Bond/Barratt SABC-B model is used with the default 10% Essbm calibration factor.

- circuit F80 = 132 mm

- circuit P80 = 180 µm

- The average ball mill work index given as 16 kWh/short ton = 17.6 kWh/tonne

- The relationship between A×b and WiRM for Andean copper porphyries can be used to determine the following rod mill work index values.

- A×b of Esperanza ore; avg= 39; becomes WiRM=14.5 kWh/tonne

- No crushing work index is given. Assume a value of 12 kWh/tonne (slightly higher than typical porphyry)

- No ore density is given. Assume similar to Los Bronces, density=2.64 t/m³

SAG mill is modelled using following:

- Austin model

- assume ore density 2.64 t/m³, same as Los Bronces

- nominal diameter 40 foot, effective grinding length 26 foot (deduct 2 ft from cylinder length)

- assume 6 inch liner effective thickness, mill speed 75% of critical

- ball charge 16% v/v; total filling 26% v/v gives the desired 92.4% utilization of motor power

Ball mill is modelled using following:

- Nordberg wet overflow model

- assume ore density 2.64 t/m³, same as Los Bronces

- nominal diameter 27 foot, effective grinding length 44.5 foot (deduct 6 inches from cylinder length)

- assume 6 inch liner effective thickness, mill speed 75% of critical

- total filling 30% v/v gives the desired 95% utilization of motor power

- Screengrab AvgOre.png

Esperanza benchmarking circuit model screen grab

Results

Only one ball mill work index is provided, claimed to be the 'average'. The predictions of the min/max range are dubious because the ball mill work index should change between hard and soft ore.

| Average ore | |

|---|---|

| Measured SAG specific energy consumption, kWh/t | |

| Predicted SAG specific energy consumption, kWh/t | |

| Difference, kWh/t | |

| Difference, % |