Benchmarking: Bond - Copper Mountain

Revision as of 05:16, 3 December 2012 by Alex Doll (talk | contribs) (Created page with "category: Benchmarking category: Bond/Barratt Model ==Benchmarking: Bond/Barratt - Copper Mountain== ===2011 SAG Conference, Mill & Motor=== ''van de Vijfeijken, ...")

Benchmarking: Bond/Barratt - Copper Mountain

2011 SAG Conference, Mill & Motor

van de Vijfeijken, M., Filidore, A., Walbert, M and Marks, A., Copper Mountain: Overview on the Grinding Mills and their Dual Pinion Mill Drives. Proceedings of the SAG 2011 Conference, September 25-28, 2011; Vancouver, Canada.

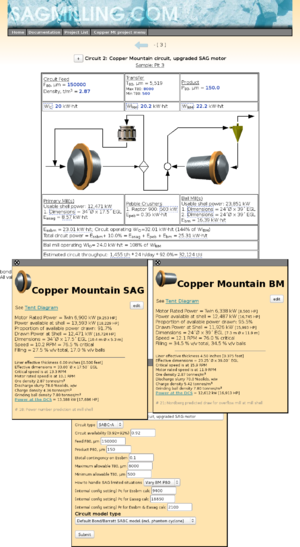

- SAG mill inside (shell) diameter: 34 ft (10.363 m)

- SAG mill effective grinding length: 17.5 ft (5.334 m)

- SAG mill design speed (corresponding to motor peak torque/power): 10.08 RPM

- SAG mill motor (original) power output: 17,000 HP (12,677 kW)

- Ball mill inside (shell) diameter: 24 ft (7.315 m)

- Ball mill effective grinding length: 39 ft (11.886 m)

- Ball mill design speed (corresponding to motor peak torque/power): 11.89 RPM

2011 SAG Conference, Process Design

Marks, A., Sams, C. and Major, K., Grinding Circuit Design for Similco Mines. Proceedings of the SAG 2011 Conference, September 25-28, 2011; Vancouver, Canada.

| Sample | Density, g/cm3 | A×b | ta | WiRM | WiBM |

|---|---|---|---|---|---|

| Pit 2 | 2.75 | 22.9 | 0.19 | 20.1 | 22.3 |

| Pit 3 | 2.87 | 20.1 | 0.16 | 20.2 | 22.2 |

- Circuit F80: 150 mm

Presentation to District 6 CMP

Morrison, R., Current Plant Conditions at Copper Mountain. Presentation to the BC/Yukon Branch Canadian Mineral Processors, November 29, 2012; Vancouver, Canada.

- Ore blend is 80% Pit 3; 20% Pit 2.

- SAG mill motors have been upgraded to total 13.8 MW by adding cooling to drive transformers (6.9 MW per motor).

- SAG mill operating with 17% v/v ball charge and 27% to 28% v/v total filling

- SAG mill operating typically 10.2 RPM.

- Ball mills operating 34% to 35% v/v total filling

- Circuit P80=150 µm (was 180 µm before SAG motor upgrade)

- Circuit throughput: 1600 t/h

Modelling

- Assume the crushing work index is similar to the rod mill: 20 (metric).

- Default SSBM contingency for SABC circuit is 0.10.

- Assume liner thickness of 6 inches in SAG, 4.5 inches in ball mill.

- Model predicted throughput: 1462 t/h on Pit 3 ore and 1452 t/h on Pit 2 ore

Result for default model conditions:

| Tonnage | |

|---|---|

| Model | 1462 t/h |

| Measured | 1600 t/h |

| Difference | 138 t/h |

| Difference | 9.0% |

Discussion

- It is noted that the SAG mill model is drawing less than 92% of available power and the ball mill model is drawing over 95%. The ball mills are likely operating at close to this power draw, but it is likely the SAG mill actual power draw (measured at the shell) is higher than 92%. Power measurements for these mills haven't been published to check against the model.

- The liner effective thickness is unknown and may be thinner than assumed — this would increase the power draw in the mills and increase the tonnage.

Model Tuning

The Bond/Barratt model is tuned using a contingency on the Single Stage Ball Mill specific energy consumption estimate (Essbm).

- The SSBM contingency factor would be back-calculated as 0.01 based on the data set above.

- Changing the SAG mill to the simplified Morrell model results in a much lower mill power draw estimate: 82.8% of rated output. This is much too low and this mill must be modelled with a higher k-factor; likely between 1.35 and 1.40. Unfortunately, without actual motor power measurements, this factor cannot be tuned.