Difference between revisions of "Benchmarking: Bond - Cadia East"

(→Modelling) |

(→Model results) |

||

| (3 intermediate revisions by one other user not shown) | |||

| Line 32: | Line 32: | ||

The mill load, ball charge and pulp density was tweaked to mimic these power draws, corresponding to: |

The mill load, ball charge and pulp density was tweaked to mimic these power draws, corresponding to: |

||

* SAG operating 9% v/v balls, 25.5% v/v total filling and 78% of critical speed (Austin model has fixed %solids) |

* SAG operating 9% v/v balls, 25.5% v/v total filling and 78% of critical speed (Austin model has fixed %solids) |

||

| − | * ball mills operating 37% v/v total filling and 70% w/w solids (fixed speed mills, 72% speed) |

+ | * ball mills operating 37% v/v total filling and 70% w/w solids (fixed speed mills, 72% of critical speed) |

| − | The ball load required to match the reported power draw is very high, and could only be achieved with a significant reduction in the trunnion diameter (using ball retaining rings). Moreover, the motors are predicted to be operating at 100.5% of their rated output power to |

+ | The ball load required to match the reported power draw is very high, and could only be achieved with a significant reduction in the trunnion diameter (using ball retaining rings). Moreover, the motors are predicted to be operating at 100.5% of their rated output power to achieve the indicated power draw. |

===Model results=== |

===Model results=== |

||

| Line 43: | Line 43: | ||

! E<sub>ball</sub> |

! E<sub>ball</sub> |

||

! E<sub>total</sub> |

! E<sub>total</sub> |

||

| + | ! Throughput |

||

|- |

|- |

||

| Model |

| Model |

||

| − | | 12. |

+ | | 12.31 kWh/t |

| − | | |

+ | | 14.94 kWh/t |

| 27.7 kWh/t |

| 27.7 kWh/t |

||

| − | | |

+ | | 1243 t/h |

|- |

|- |

||

| Measured |

| Measured |

||

| Line 57: | Line 58: | ||

|- |

|- |

||

| Difference |

| Difference |

||

| − | | 1. |

+ | | 1.71 kWh/t |

| − | | 1. |

+ | | 1.74 kWh/t |

| 3.9 kWh/t |

| 3.9 kWh/t |

||

| − | | - |

+ | | -239 t/h |

|- |

|- |

||

| Difference |

| Difference |

||

| − | | |

+ | | 16.13% |

| − | | |

+ | | 13.18% |

| − | | 16% |

+ | | 16.39% |

| − | | -13% |

+ | | -16.13% |

|} |

|} |

||

| + | <gallery> |

||

| − | The predicted transfer size needed to balance the power draw between primary & second mills is very coarse, 5 mm. |

||

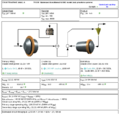

| + | File:CadiaEast.png|thumb|Cadia East circuit |

||

| + | File:CadiaEast-SAG.png|thumb|Cadia East SAG mill |

||

| + | File:CadiaEast-BM.png|thumb|Cadia East Ball mill |

||

| + | File:Cadia-Pebble.png|thumb|Cadia East Pebble crusher |

||

| + | </gallery> |

||

| + | |||

| + | The predicted transfer size needed to balance the power draw between primary & second mills is very coarse, 5 mm. |

||

===Discussion=== |

===Discussion=== |

||

Latest revision as of 00:55, 22 May 2020

Contents

Benchmarking: Bond/Barratt - Cadia

Engelhardt, D., Robertson, J., Lane, G., Powwel, M.S. and Griffin, P., Cadia Expansion - From open pit to block cave and beyond. Proceedings of MetSoc 2012.

Design criteria and plant trial of underground Cadia East ore

Ore characterization

- blased underground ore, secondary crushed to 80 mm.

- WiC = 30 (metric)

- WiRM = 26.5 (metric)

- WiBM = 21.4 (metric)

- DWI = 9.9

- density = 2.7 t/m³

The ore was reported blasted undergrond (block caving had not yet started). Particle size distribution given as two points which confirm a Bond-compatible "root-2" PSD.

- 80% passing 80 mm

- 20% passing 5 mm

Modelling

Details of the mill operating conditions are not given, but the power draw at the shell is given.

- 15.737 MW SAG mill power draw

- 19.509 MW ball mill power draw

Circuit operating conditions:

- F80 = 80 mm

- P80 = 140 µm

- instantaneous throughput = 1482 t/h

The mill load, ball charge and pulp density was tweaked to mimic these power draws, corresponding to:

- SAG operating 9% v/v balls, 25.5% v/v total filling and 78% of critical speed (Austin model has fixed %solids)

- ball mills operating 37% v/v total filling and 70% w/w solids (fixed speed mills, 72% of critical speed)

The ball load required to match the reported power draw is very high, and could only be achieved with a significant reduction in the trunnion diameter (using ball retaining rings). Moreover, the motors are predicted to be operating at 100.5% of their rated output power to achieve the indicated power draw.

Model results

| ESAG | Eball | Etotal | Throughput | |

|---|---|---|---|---|

| Model | 12.31 kWh/t | 14.94 kWh/t | 27.7 kWh/t | 1243 t/h |

| Measured | 10.6 kWh/t | 13.2 kWh/t | 23.8 kWh/t | 1482 t/h |

| Difference | 1.71 kWh/t | 1.74 kWh/t | 3.9 kWh/t | -239 t/h |

| Difference | 16.13% | 13.18% | 16.39% | -16.13% |

The predicted transfer size needed to balance the power draw between primary & second mills is very coarse, 5 mm.

Discussion

There is a substantial difference between the survey and the predictions. Some observations:

- The rod mill work index was determined on an apparatus with smooth liners. This can cause a difference of 2-3 kWh/t versus the wave-liner apparatus specified by Bond. Using a rod mill work index of 24.0 kWh/t gives Etotal = 26.8 kWh/t; still 13% high.

- The Essbm predicts the energy required for a "standard" secondary crushing & ball milling plant that is believed to be one of the most energy efficient types of grinding circuits. This ore has Essbm = 24.3 kWh/t which is still less than the survey Etotal. Very odd result that a SABC circuit is more efficient than an SSBM (ergo, HPGR) circuit on such a hard ore.