Model:Morrell Mi SMC SAG

Contents

Morrell SMC SAG & ball mill Model

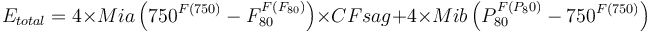

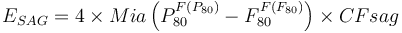

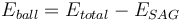

This is a SAG or AG mill plus ball mill model that estimates the specific energy consumption (ESAG) using the equations of Morrell (2004).

Testwork Required

- The SMC™ test, stored in the "DWT" testwork table (Drop Weight Test).

- Bond ball mill work index. The method requires all the elements of the ball mill work index test to be filled in:

- Ball mill Wi test closing screen size, umclosing, µm

- Ball mill Wi test product size, P80, µm

- Ball mill Wi test feed size, F80, µm

- Ball mill Wi grams per revolution at test conclusion, gpr

Formulae

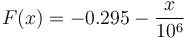

The method is superficially similar to Bond (among other models), but with a variable exponent on size defined by:

Where x is the particle 80% passing size in µm.

CFsag calibration factor

The CFsag factor is used to reflect the effect of pebble crushing and pre-crushing on the overall circuit performance. This value is automatically selected if you leave this field blank in the model configuration settings.

- Base value, SAB circuit (no pebble crushing, ~6 inch SAG feed), CFsag = 1.00

- Pebble crushing, SABC circuit, CFsag = 0.95

Transfer size

Morrell specifically discourages use of transfer size in calculations such as those in SAGMILLING.COM for a variety of reasons (see discussion in Morrell, 2011). Unfortunately, the alternative method proposed by Morrell is a complex equation that requires pre-selected mill sizes and a series of unpublished calibration factors. This alternative method is not practical for the calculations in SAGMILLING.COM, so a transfer size approach is used instead.

The modelled transfer sizes are probably "Bond-compatible" and not similar to what would be measured directly in a plant survey. Plant survey results would need to be subjected to a phantom cyclone calculation before they are comparable to the model predictions.