Model:Amelunxen SGI

Amelunxen SGI Model

This is a SAG or AG mill plus ball mill model that estimates the specific energy consumption (ESAG) using the equation by Amelunxen (2014) and the classical Bond work index equation substituting CFball in the place of the Rowland efficiency factors. The model requires manual calibration factors for both equations (CFSAG and CFball, respectively).

Testwork Required

Formulae

CFsag calibration factor

The CFsag factor is used to reflect the effect of pebble crushing and pre-crushing on the overall circuit performance.

- Base value, SAB circuit (no pebble crushing, ~6 inch SAG feed), CFsag = 1.00

- Pebble crushing, SABC circuit, CFsag = 0.85

- Pre-crushing, (fine SAG feed, -2½ inch SAG feed), CFsag = 0.90

- Pre-crushing and pebble crushing, CFsag = 0.85 × 0.90 = 0.77

CFball calibration factor

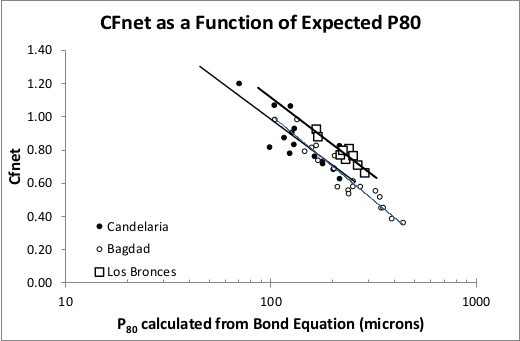

The CFball is a manually picked value used to lump the phantom cyclone effect and the variety of Rowland efficiency factors into a single factor. This value is usually picked based on a mill survey, or taken from a diagram such as Figure 5 from Becerra & Amelunxen (2012)Bibliography, reproduced below.

(CFnet is the term used by Becerra & Amelunxen for CFball)

(CFnet is the term used by Becerra & Amelunxen for CFball)

Transfer size

The transfer size assumed in a Amelunxen SGI model is described as being "as would be measured in a plant survey" (uncorrected for the extra fines, the phantom cyclone effect). This is different to the basis of the various Bond models where the transfer size is a synthetic value that implies the removal of the extra fines.

In practical terms, running an SGI model will require relaxing the upper T80 constraints (the default constraints are tuned to the Bond models). Upper limits of 5000 µm or 6000 µm are not uncommon when simulating Andean copper porphyry type ores.