Benchmarking: Bond - Tropicana

Contents

Benchmarking: Bond/Rowland SSBM model - Tropicana HPGR circuit

Sources, SAG 2015 conference

Koch, F., Siddall, L., Lovatt, I., Giddy, M. and DiTrento, M. RAPID RAMP-UP OF THE TROPICANA HPGR CIRCUIT, SAG 2015 paper number 70.

Gardula, A., Das, D., DiTrento, M. and Joubert, S. FIRST YEAR OF OPERATION OF HPGR AT TROPICANA GOLD MINE – CASE STUDY, SAG 2015 paper number 69

- Primary crusher product (model F80) approximately 150 mm

- Secondary crushing circuit 1×XL900 crusher

- Tertiary crushing circuit 1×2.0 m by 1.85 m HPGR, with two 2.2 MW drives

- Fine screen aperture 4 mm, 57% passing 3 mm.

- Ball mill 24 ft diam by 43 ft long with twin-pinion 7 MW SER v/s drives

Average Primary Ore sample tested at ALS Ammtec gave following determinations:

- UCS 76.7 MPa

- WiC 16.1 (metric)

- WiRM 19.4 (metric, but based on non-standard liner geometry)

- WiRM would be 15.0 (metric, Bond RM geometry) based on A×b = 36.1

- WiBM 17.6 (metric)

- JKDWT: A×b 36.1, ta 0.40

- SMC test™ A×b 41.4, DWi 7.21

- Bond Ai 0.291

Plant design criteria:

- primary crusher product (circuit F80) = 150 mm

- hydrocyclone overflow (circuit P80) = 75 µm

- ball mill using WRIM with Slip Energy Recovery and gearbox, assume 0.95 × 0.97 efficiency = 0.9215 conversion DCS power to shell.

Plant DCS data Jan 2014 to Mar 2015:

- secondary crusher specific energy consumption 0.4 kWh/t

- assume product size 35 mm

- power draw back-calculates to 763 t/h × 0.4 = 305 kW (45% of available power)

- ball mill throughput 734 t/h (use this as overall throughput at 91.2% availability)

- HPGR specific energy consumption, EHPGR = 2.60 kWh/t

- energy associated to auxiliary equipment in sec crushing & HPGR = 0.70 + 1.08 = 1.78 kWh/t

- HPGR circuit product size assumed (T80) 3.5 mm

- ball mill drawing about 14 MW (assumed DCS, works out to 13.0 MW at mill shell)

- Eball = 16.77 kWh/t at shell (18.2 kWh/t at DCS)

Modelling

Use the Bond/Rowland single stage ball mill circuit model with the HPGR-BM flowsheet.

Ball mill model:

- Use the Nordberg wet overflow ball mill model

- Quantity 1

- Mill dimensions, diameter 24 ft, EGL 43 ft

- motor mechanical efficiency 0.97; motor efficiency to DCS 0.95

- Assume 6 inch liner thickness, 7.80 t/m3 ball density.

- Assume speed is 75% of critical and load is 32% v/v

Secondary crusher model:

- Quantity 1.

- XL900 crushers, use 900 HP motor.

- set mechanical efficiency to 0.45.

- ESecCrush of 0.40 kWh/t

HPGR model:

- Quantity 1

- HPGR motor 4400 kW (actually 2 × 2200 kW)

- Adjust the mechanical efficiency to get ETertCr of 2.6 kWh/t (EHPGR of 2.6 kWh/t),

- results is mechanical efficiency of 0.44.

Bond/Rowland SSBM Circuit model:

- Set the crusher product size to 3500 µm

- Circuit feed size 150 000 µm and product size 75 µm

- Adjust the Essbm calibration factor to zero (0)

- Result is 745 t/h circuit throughput with Etotal of 20.5 kWh/t (excluding auxiliary equipment)

- Predicts 1% increase in ball mill operating work index (17.75) versus laboratory Wi (17.5).

Discussion

Essbm equation calibration

No correction is made for the smooth liner in the rod mill work index apparatus. This rod mill work index will be conservative (probably high by more than 2 units).

Microcracking/phantom cyclone/ball mill performance

The predicted 1% increase in WiO fits nicely with the observation at Tropicana that "The range over five field tests was 0% to 8% higher power consumption when compared to the theoretical prediction."

Secondary crushers, operating work index

The Bond (impact) crushing work index is given as 16.1 based on a laboratory determination. Use the circuit survey data to compare the operating work index to this laboratory determination.

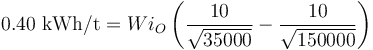

The reported specific power consumption of the XL900 crusher is 0.40 kWh/t. The secondary crusher is assumed to process a 150 mm primary crushed feed into a 35 mm secondary crushed product. Back-calculating the operating work index of the crusher gives:

Solving for WiO gives 2.8 kWh/tonne (versus laboratory determination 16.1 kWh/t).