Conversions between test types

Converting between comminution test types

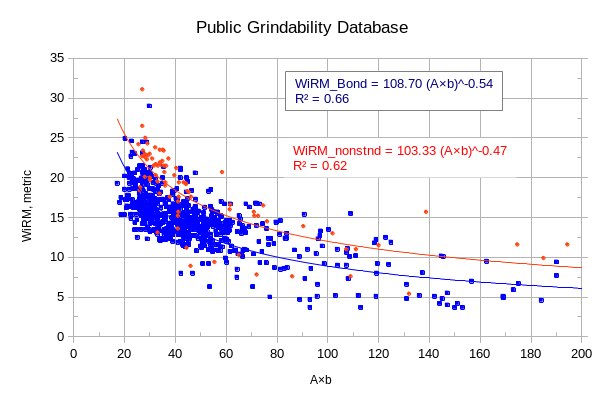

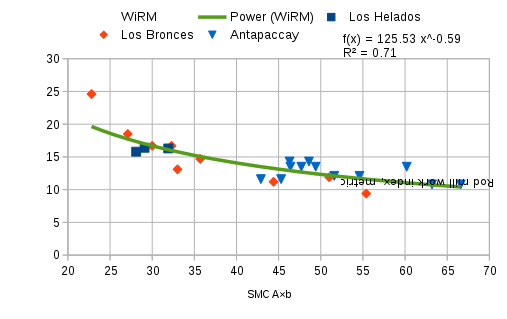

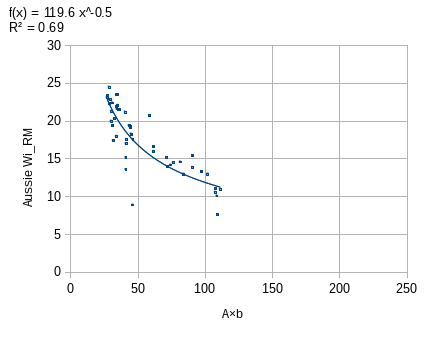

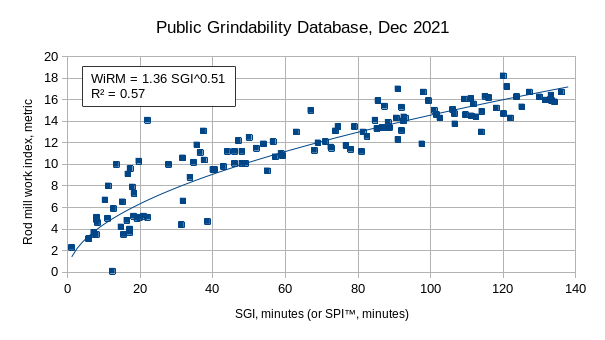

Different tests are used in different grindability models for substantially the same purposes. Certain grindability tests are compatible with other tests, and an approximate conversion can be established by comparing to a database of testwork.

The determination of which tests are compatible with other tests is largely a function of the particle size of the specimens subjected to testing.Doll & Barratt, 2011 Ore properties also play a role because some tests are sensitive to changes in ore density and other tests operate with a biased sample consisting only of competent pieces.

Medium size class

The three tests in the medium size class are:

- Bond rod mill work index (WiRM)

- SAG Grindability index (SGI) or SAG Power index (SPI™)

- Drop weight test, both JK and SMC (A×b, DWI, Mia, etc)

Extra parameters for Drop Weight Tests (DWT)

A drop weight test is usually interpreted using a plot of the %passing 10% of the original particle size (t10) versus the energy of the weight that impacted the specimen (Ecs). These are plotted at fit to an exponential relationship with fitting parameters "A" (coefficient) and "b" (exponent).

There are several derived parameters that are commonly used in modelling that can be calculated using these A and b values, usually based on the slope of the curve at the origin of the plot. This is commonly referred to as the (A×b) value.

- DWI = (density, kg/L) × 96.70 × (A×b)-0.992

- Mia = 392.18 × (A×b)-0.814

- Mih = 580.6 × (A×b)-1.000

- Mic = 305.78 × (A×b)-1.005