General concepts

General Concepts

Each grinding calculation consist of several components that interact with each other:

- A 'project' to which each item of 'testwork' and each 'circuit' is assigned. This effectively partitions a much larger database into a manageable mine-specific data set.

- A 'Testwork' database containing a list of samples, their laboratory results and optional geological information.

- Samples that have testwork results required to feed the selected specific energy model are combined into a 'query' table that consists of all samples capable of being simulated in the circuit model.

- A 'circuit' which acts as a container for two model components:

- A 'specific energy model' that estimates how much energy is required to grind ore from a feed size to a product size.

- One or more 'mill power draw models' that estimates how much power is evolved by a mill of a particular geometry under specified operating conditions.

Example structure, SAB model

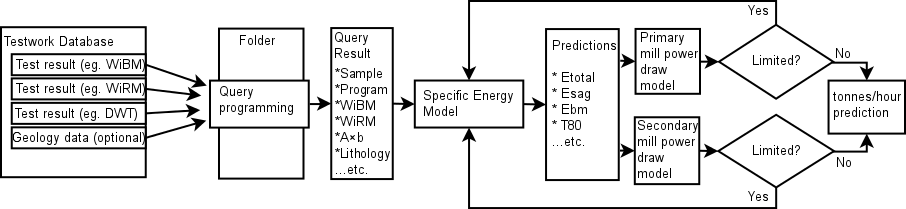

This is an example diagram explaining the different components of a project consisting of a batch of test results and a Bond-based SAG mill-ball mill circuit model.

The Bond model requires three Bond work index values in order for a sample to appear in the 'query table' of samples. This query table is the sub-set of all samples that is capable of being run in a particular model (because the correct types of test results are all available).

The specific energy model estimates the specific energy values for the components of the circuit (SAG & ball mills). Next, the website calculates the amount of power evolved by each mill (SAG and ball). The throughput of each mill stage is evaluated (power evolved in the mill divided by the specific energy) and if one particular stage is "limiting", then the calculation returns to the specific energy model to figure out what to do (if anything) to the stage that isn't limiting. For example, if the SAG mill is limiting throughput, then a fixed-speed ball mill will over-grind the ore to a finer P80 than what the circuit is targetting.

The final model output is a set of specific energy predictions for the circuit, mill power draw for each of the mills in the circuit, the throughput and the intermediate and final grind sizes.