Creating a circuit model

Access Level

Users must have "write" permissions to a project to create circuits within that project. Ask your Administrator for permission to edit a project if you do not see the "add circuit" buttons.

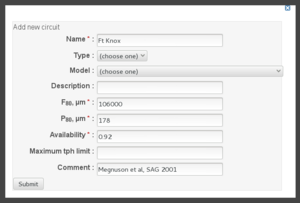

Creating a Circuit Model

A circuit model is part of a project that matches grinding testwork to circuit specific energy consumption models and mill power draw models. There are several types of circuit models available depending on the type of testwork and the nature of the grinding circuit being simulated.

Steps in creating a circuit model

From the main menu of the project you want to create a new circuit for,

- Click the "Add new circuit" button

- Fill in the form. Fields are:

- Name: the name of this circuit (should be unique within a Project)

- Type: the overall type of circuit (SAB, SABC, etc.)

- Model: which circuit specific energy model to use (see Choosing the right model below. Should always match the Type selected.

- Description: (optional) extra information that is not displayed on reports.

- F80: circuit feed size (usually primary or pre-crusher crusher product).

- P80: circuit product size (cyclone overflow for SAB/SABC circuits)

- Maximum tph limit: (not presently implemented)

- Comment: (optional) extra information that is displayed on reports.

- T80 min: (optional) overwrites the model's transfer size limitation.

- T80 max: (optional) overwrites the model's transfer size limitation.

- A circuit model page including a flowsheet will appear. Next step is to add mills to the circuit:

- Create a new SAG mill by clicking the "+ primary mill" button. Further instructions.

- Continue adding mills (and pebble crushers) to the new circuit.

- The mills assigned to this new circuit are listed and can be edited (if necessary) by clicking the looking glass icons.

Choosing the right model

You must choose an appropriate circuit specific energy model from the drop-down list when creating or editing a circuit model. Note that the list does not validate based on your mill selection. Do not choose an "SABC" type circuit model if no crusher exists in the circuit.

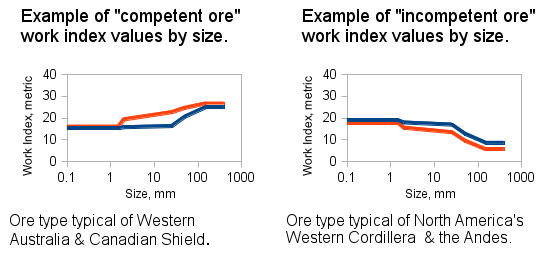

Multiple specific energy models available for SAG mill circuits and the choice of which to use depends on the type of ore being processed:

- Optimized Bond/Barratt (for incompetent ores)

- Raw Bond/Barratt (for competent ores)

{future: SMC and SGI models will be added}

In general, the "Optimized Bond/Barratt" models are calibrated to copper porphyry projects in the Andes and western North America where the rocks are considered to be "low competency". The model has also been checked against several gold mines and works well as long as the crushing work index is generally less than the rod and ball mill work index values. Highly competent ores, where the crushing work index is greater than the rod and ball mill work indices, should use a "Raw Bond/Barratt" model {or the "SMC model" which will be added in the future}.

Choosing the right flowsheet

For a SAG and ball mill circuit (flowsheet type SAB):

- Use the Bond/Barratt SAB models if you have Bond work index test results (requires ball mill work index, rod mill work index and impact crushing work index).

- [future SMC models, not available yet] Use the SAB SMC models if you have SMC Mi test results (Mia and Mib)

For a SAG, pebble crusher and ball mill circuit (flowsheet type SABC):

- Use the Bond/Barratt SABC models if you have Bond work index test results (requires ball mill work index, rod mill work index and impact crushing work index).

- Use the Morrell SMC SABC models if you have SMC Mi test results (Mia and Mib).

For a SAG mill circuit (single-stage) (flowsheet type OCSAG or SSSAG):

- Use the Bond/Barratt single-stage SAG model if you have Bond work index test results (requires ball mill work index, rod mill work index and impact crushing work index).

- Use the Morrell SMC single-stage SAG model if you have an SMC Mia test result.

For a rod mill and ball mill circuit [future model, not available yet]:

- Use the Bond Rod/Ball model (requires Bond work index values for rod milling and ball milling)

For a single-stage ball mill circuit:

- Use the Bond/Rowland single stage ball mill model (requires Bond work index values for rod milling and ball milling)

Random instructions

When you switch back and forth between an Optimized Bond/Barratt SAB model and a Optimized Bond/Barratt SABC model, and if you are using the default Essbm calibration factor, then you must manually reset the calibration factor when you change the circuit type. If you are using a calibration factor determined by a mill survey, then the actual values you insert for this value should be based on the survey.

- Optimized Bond/Barratt SABC model enter an Essbm calibration factor = 0.10

- Optimized Bond/Barratt SAB model enter an Essbm calibration factor = 0.15