Difference between revisions of "Benchmarking: Morrell Mih - Tropicana"

(→Modelling) |

(→Modelling) |

||

| Line 79: | Line 79: | ||

'''HPGR model:''' |

'''HPGR model:''' |

||

| − | * Quantity 1 |

+ | * Quantity 1. |

| − | * HPGR motor 4400 kW (actually 2 × 2200 kW) |

+ | * HPGR motor 4400 kW (actually 2 × 2200 kW). |

| − | * set mechanical efficiency to 0.50 to avoid limiting the throughput |

+ | * set mechanical efficiency to 0.50 to avoid limiting the throughput (would be 0.45 to match plant kW draw). |

Revision as of 16:02, 14 June 2018

Contents

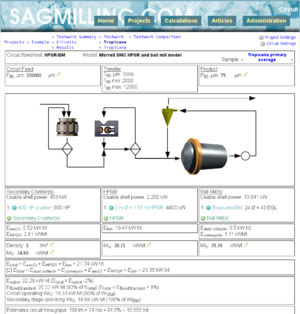

Benchmarking: Morrell SMC and ball mill model - Tropicana HPGR circuit

Sources, SAG 2015 conference

Koch, F., Siddall, L., Lovatt, I., Giddy, M. and DiTrento, M. RAPID RAMP-UP OF THE TROPICANA HPGR CIRCUIT, SAG 2015 paper number 70.

Gardula, A., Das, D., DiTrento, M. and Joubert, S. FIRST YEAR OF OPERATION OF HPGR AT TROPICANA GOLD MINE – CASE STUDY, SAG 2015 paper number 69

- Primary crusher product (model F80) approximately 150 mm

- Secondary crushing circuit 1 × XL900 crusher

- Tertiary crushing circuit 1 × 2.0 m by 1.85 m HPGR, with two 2.2 MW drives

- Fine screen aperture 4 mm, 57% passing 3 mm.

- Ball mill 24 ft diam by 43 ft long with twin-pinion 7 MW SER v/s drives

Average Primary Ore sample tested at ALS Ammtec gave following determinations:

- UCS 76.7 MPa

- WiC 16.1 (metric)

- WiRM 19.4 (metric, but based on non-standard liner geometry)

- WiBM 17.6 (metric)

- JKDWT: A×b 36.1, ta 0.40

- SMC test™ A×b 41.4, DWi 7.21

- Bond Ai 0.291

Plant design criteria:

- primary crusher product (circuit F80) = 150 mm

- hydrocyclone overflow (circuit P80) = 75 mm

- ball mill using WRIM with Slip Energy Recovery and gearbox, assume 0.95 × 0.97 efficiency = 0.9215 conversion DCS power to shell.

Plant DCS data Jan 2014 to Mar 2015:

- secondary crusher specific energy consumption 0.4 kWh/t

- assume product size 35 mm

- power draw back-calculates to 763 t/h × 0.4 = 305 kW (45% of available power)

- ball mill throughput 734 t/h (use this as overall throughput at 91.2% availability)

- HPGR specific energy consumption, EHPGR = 2.60 kWh/t

- power draw back-calculates to 763 t/h × 2.60 = 1984 kW (45% of available power)

- energy associated to auxiliary equipment in sec crushing & HPGR = 0.70 + 1.08 = 1.78 kWh/t

- HPGR circuit product size assumed (T80) 3.5 mm

- ball mill drawing about 14 MW (assumed DCS, works out to 13.0 MW at mill shell)

- Eball = 16.77 kWh/t at shell (18.2 kWh/t at DCS)

Modelling

Use the Morrell SMC HPGR and ball mill circuit model with the HPGR-BM flowsheet. The relationship between a drop weight test A×b and the Mia, Mic and Mih factors (fitted to Doll, 2016 published information) is:

- Mia = 390.89× (A×b)-0.81

- Mih = 577.0 × (A×b)-1.00

- Mic = 303.48 × (A×b)-1.00

Using the average A×b = 38.75 for the Primary-Average ore type gives Mia = 20.21 kWh/t, Mic = 7.75 kWh/t and Mih = 14.89 kWh/t. (using an arithmetic average of A×b values is not recommended generally, but won't make a difference to the precision of this survey data).

Convert the ball mill work index to an Mib value of 25.39 kWh/t by assuming the test conditions suitable for a Wi of 17.6 metric units:

- BM test F80: 2300 µm

- BM test P80: 75 µm (assume same as the circuit design)

- BM test grams per revolution: 1.01 (calculated based on above)

The model predictions are:

- Secondary crushing, EsecCr = 0.63 × MiEquation(Mic = 7.75, F80 = 35000 µm, P80 = 3500 µm) × 1.0 = 0.52 kWh/t

- HPGR, Ehpgr = 0.84 × MiEquation(Mih = 14.89, F80 = 35000 µm, P80 = 6000 µm) × 1.0 = 2.81 kWh/t

- Ball mill, Eball = MiEquation(20.21, 750.0, 3500.0) × 1.000 + MiEquation(25.390, 75.0, 750.0) = 18.41 kWh/t

Ball mill model:

- Use the Nordberg wet overflow ball mill model

- Quantity 1

- Mill dimensions, diameter 24 ft, EGL 43 ft

- motor mechanical efficiency 0.97; motor efficiency to DCS 0.95

- motor power, 7000 kW, twin-pinion drives

- Assume 6 inch liner thickness, 7.80 t/m3 ball density.

- Assume speed is 75% of critical and load is 32% v/v

Secondary crusher model:

- Quantity 1.

- XL900 crushers, use 900 HP motor.

- set mechanical efficiency to 0.6 so that sec crushing isn't limiting the throughput (would be 0.45 to match plant kW draw).

HPGR model:

- Quantity 1.

- HPGR motor 4400 kW (actually 2 × 2200 kW).

- set mechanical efficiency to 0.50 to avoid limiting the throughput (would be 0.45 to match plant kW draw).

Morrell SMC HPGR and Ball Mill Circuit model:

- Set the crusher product size to 35 000 µm and the transfer size to 3500 µm.

- Circuit feed size 150 000 µm and product size 75 µm

- (optional) Set the conveyor lift height to 30 m

- Result is 745 t/h circuit throughput with Etotal of 20.5 kWh/t (excluding auxiliary equipment)

- Predicts 1% increase in ball mill operating work index (17.75) versus laboratory Wi (17.5).

Discussion

The comparison of predicted specific energy consumption versus actual observed in the surveys is given below:

| Model Prediction | Survey Actual | Difference | |

|---|---|---|---|

| EsecCr | 0.52 kWh/t | 0.40 kWh/t | model 30% high |

| Ehpgr | 2.83 kWh/t | 2.60 kWh/t | model 9% high |

| Eball | 18.36 kWh/t | 16.77 kWh/t | model 9% high |

| Etotal | 21.70 kWh/t | 19.77 kWh/t | model 10% high |

The Morrell model results using SMC and ball mill laboratory tests is about 10% conservative versus the survey results. This is not a bad result considering the variation in laboratory result (A×b) observed and how neither the SMC test nor the ball mill test were originally created to deal with HPGR technology.

The throughput determined by the ball mill treatment rate is 710 t/h, versus observed 734 t/h (model is 3% conservative, an excellent prediction).

Microcracking/phantom cyclone/ball mill performance

The predicted 6% increase in WiO fits nicely with the observation at Tropicana that "The range over five field tests was 0% to 8% higher power consumption when compared to the theoretical prediction."