Difference between revisions of "General concepts"

(Created page with "==General Concepts== Each grinding calculation consist of several components that interact with each other: * A 'Testwork' database containing the laboratory results and o...") |

(→General Concepts) |

||

| (8 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

==General Concepts== |

==General Concepts== |

||

| − | Each grinding calculation consist of several components that interact with each other: |

+ | Each grinding calculation consist of several components that interact with each other, all contained in your company's database: |

| + | * A '[[Creating a project|project]]' to which each item of 'testwork' and each 'circuit' is assigned. This effectively partitions a much larger database into a manageable mine-specific data set. |

||

| − | * A '[[Testwork]]' database containing the laboratory results and optional geological information that describes the samples taken for testing. |

||

| + | * A '[[Testwork]]' database containing a list of samples, their laboratory test results and optional geological information. |

||

| − | * A 'folder' that contains the programming to convert testwork into '[[Testwork:_Queries|queries]]'. The folder you choose to use will be determined by which specific energy consumption model you want to run. |

||

| + | ** Samples that have testwork results required to feed the selected specific energy model are combined into a 'query' that consists of all samples capable of being simulated in the circuit model. |

||

| + | ** The testwork database is divided into individual test 'programs' and all test results are assigned to a program. Think of a test program as a container that you assign the tests to inside of a project. |

||

* A '[[Creating a circuit model|circuit]]' which acts as a container for two model components: |

* A '[[Creating a circuit model|circuit]]' which acts as a container for two model components: |

||

** A '[[Specific energy consumption models|specific energy model]]' that estimates how much energy is required to grind ore from a feed size to a product size. |

** A '[[Specific energy consumption models|specific energy model]]' that estimates how much energy is required to grind ore from a feed size to a product size. |

||

** One or more '[[mill power draw models]]' that estimates how much power is evolved by a mill of a particular geometry under specified operating conditions. |

** One or more '[[mill power draw models]]' that estimates how much power is evolved by a mill of a particular geometry under specified operating conditions. |

||

| + | [[File:DatabaseStructure.svg]] |

||

| − | [[file:Sagmilling-modelstructure.png]] |

||

| + | The database you are using is shared with your organization, but controlled by your [[:Category:Administration|Administrator]] who will assign the ability to view and modify data in the database. |

||

| − | Different 'circuit' configurations can be run against the 'query' result. For example, two different circuits can have different sized mills. Different variations on the 'specific energy model' can test different product sizes or types of circuit configurations. |

||

| + | |||

| + | ==Example structure, SAB model== |

||

| + | This is an example diagram explaining the different components of a project consisting of a batch of test results and a Bond-based SAG mill-ball mill circuit model. |

||

| + | |||

| + | [[file:Sagmilling-modelstructure.png]] |

||

| + | The Bond model requires three Bond work index values in order for a sample to appear in the 'query table' of samples. This query table is the sub-set of all samples that is capable of being run in a particular model (because the correct types of test results are all available). |

||

| − | Clients with a large amount of data covering a variety of different orebodies (head office or consultant licenses) have an extra component: |

||

| − | * A '[[Creating a project|project]]' to which each item of 'testwork' and each 'circuit' is assigned to a particular project. This effectively partitions a much larger database into a manageable mine-specific data set. |

||

| + | The specific energy model estimates the specific energy values for the components of the circuit (SAG & ball mills). Next, the website calculates the amount of power evolved by each mill (SAG and ball). The throughput of each mill stage is evaluated (power evolved in the mill divided by the specific energy) and if one particular stage is "limiting", then the calculation returns to the specific energy model to figure out what to do (if anything) to the stage that isn't limiting. For example, if the SAG mill is limiting throughput, then a fixed-speed ball mill will over-grind the ore to a finer P80 than what the circuit is targetting. |

||

| − | ===Intellectual Property=== |

||

| − | The grinding circuit models on SAGMILLING.COM consist of programming and data partitioned into two areas: |

||

| − | * Your client area, which contains: |

||

| − | ** Your private database which contains the testwork database, the circuits you have run in your private area along with the output (collectively, the "database"). |

||

| − | ** (optionally) Any private mill power draw model or specific energy consumption model ("models") |

||

| − | ** (optionally) Any query folder that was programmed specifically for your private area ("folders"). |

||

| − | ** (optionally) A specific branding assigned to your model, would re-format the output of the basic user interface to apply your company's specific branding (in programming terms, the "theme"). |

||

| − | * The pubic area base models and user interface that are available to all clients. |

||

| + | The final model output is a set of specific energy predictions for the circuit, mill power draw for each of the mills in the circuit, the throughput and the intermediate and final grind sizes. |

||

| − | The items in your client area are only accessible by people to whom you account administrator has assigned an ID and password combination. Programmers at SAGMILLING.COM generally have maintenance access to models and databases, for example, to make database backups and to confirm that the models are operating correctly. The privacy of your data is important, and SAGMILLING.COM promises to not access your data for reasons other than maintenance and to make sure the programming is working properly. |

||

Latest revision as of 18:44, 29 August 2023

General Concepts

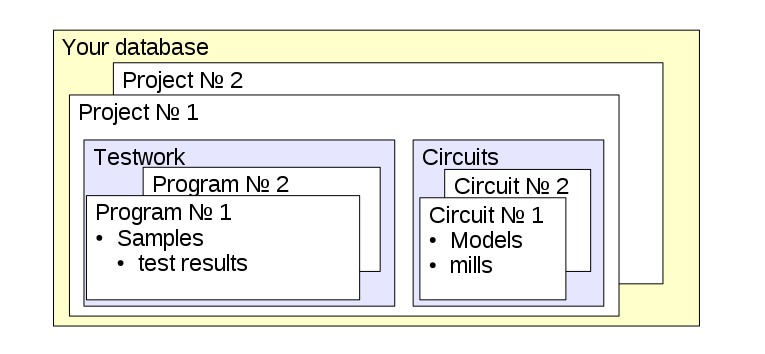

Each grinding calculation consist of several components that interact with each other, all contained in your company's database:

- A 'project' to which each item of 'testwork' and each 'circuit' is assigned. This effectively partitions a much larger database into a manageable mine-specific data set.

- A 'Testwork' database containing a list of samples, their laboratory test results and optional geological information.

- Samples that have testwork results required to feed the selected specific energy model are combined into a 'query' that consists of all samples capable of being simulated in the circuit model.

- The testwork database is divided into individual test 'programs' and all test results are assigned to a program. Think of a test program as a container that you assign the tests to inside of a project.

- A 'circuit' which acts as a container for two model components:

- A 'specific energy model' that estimates how much energy is required to grind ore from a feed size to a product size.

- One or more 'mill power draw models' that estimates how much power is evolved by a mill of a particular geometry under specified operating conditions.

The database you are using is shared with your organization, but controlled by your Administrator who will assign the ability to view and modify data in the database.

Example structure, SAB model

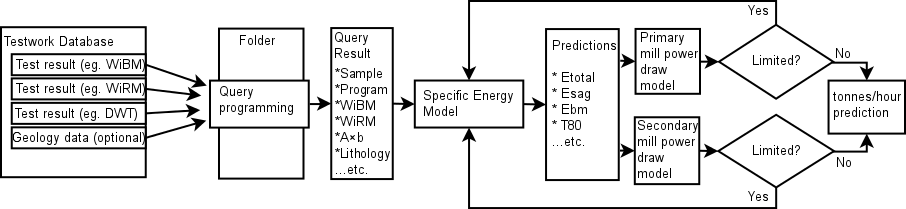

This is an example diagram explaining the different components of a project consisting of a batch of test results and a Bond-based SAG mill-ball mill circuit model.

The Bond model requires three Bond work index values in order for a sample to appear in the 'query table' of samples. This query table is the sub-set of all samples that is capable of being run in a particular model (because the correct types of test results are all available).

The specific energy model estimates the specific energy values for the components of the circuit (SAG & ball mills). Next, the website calculates the amount of power evolved by each mill (SAG and ball). The throughput of each mill stage is evaluated (power evolved in the mill divided by the specific energy) and if one particular stage is "limiting", then the calculation returns to the specific energy model to figure out what to do (if anything) to the stage that isn't limiting. For example, if the SAG mill is limiting throughput, then a fixed-speed ball mill will over-grind the ore to a finer P80 than what the circuit is targetting.

The final model output is a set of specific energy predictions for the circuit, mill power draw for each of the mills in the circuit, the throughput and the intermediate and final grind sizes.