HPGR or SAG?

HPGR or SAG?

Choosing an appropriate grinding configuration is important for conceptual design. Here are some things to consider when making the choice between an HPGR-ball mill circuit and a SAG-ball mill circuit.

Work index ratios

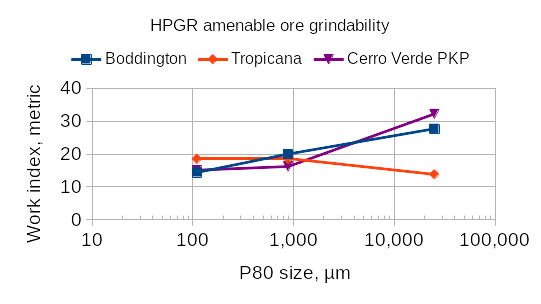

Having a hard ore is not a valid reason for choosing an HPGR circuit, the ore must be hard in a certain way. More specifically, it should have a rod mill work index greater than the ball mill work index, and a ball mill work index below 20 metric units:

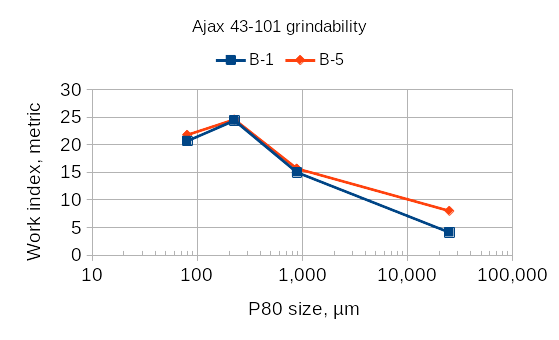

A SAG-amenable ore has the opposite orientation, the rod mill work index should be equal to, or less than the ball mill work index. Ajax is a British Columbia copper porphyry with a strong signal that it would make an efficient SAG circuit.

A low crushing work index is helpful for SAB and SABC circuits, as in the Ajax example.

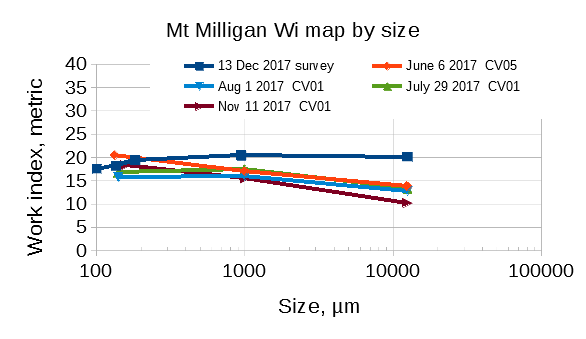

A project where the rod mill and ball mill work index values are similar, and where both are high can go either way. Example of this are Mt Milligan (SAG plant) and Tropicana (HPGR plant) where local conditions (E.g. price of power, climate) make the choice based on a financial evaluation.

Effect on the ball mill

HPGR and SAG mills are used to make feed for a ball mill. The HPGR usually has a coarser transfer size than a SAG, meaning it puts more load on the ball mill. The SAG mill's "phantom cyclone" effect is usually greater than the "microcracking" effect in an HPGR until you get to really hard material where both of these effects turn negative (industrial ball mill operating work index is greater than the laboratory ball mill work index).

If the ball mill work index is significantly higher than the rod mill work index (like the Ajax example, above), then HPGR is a poor choice.